Quality

- Home

- Quality

Good manufacture

Raw material

Given the excellent relationship with our main electrical steel manufactures in the world, Specialacciai guarantees high quality and reliability of the material for its production. The material is accepted, qualified and validated through internal quality controls that allow the traceability during the whole manufacturing process.

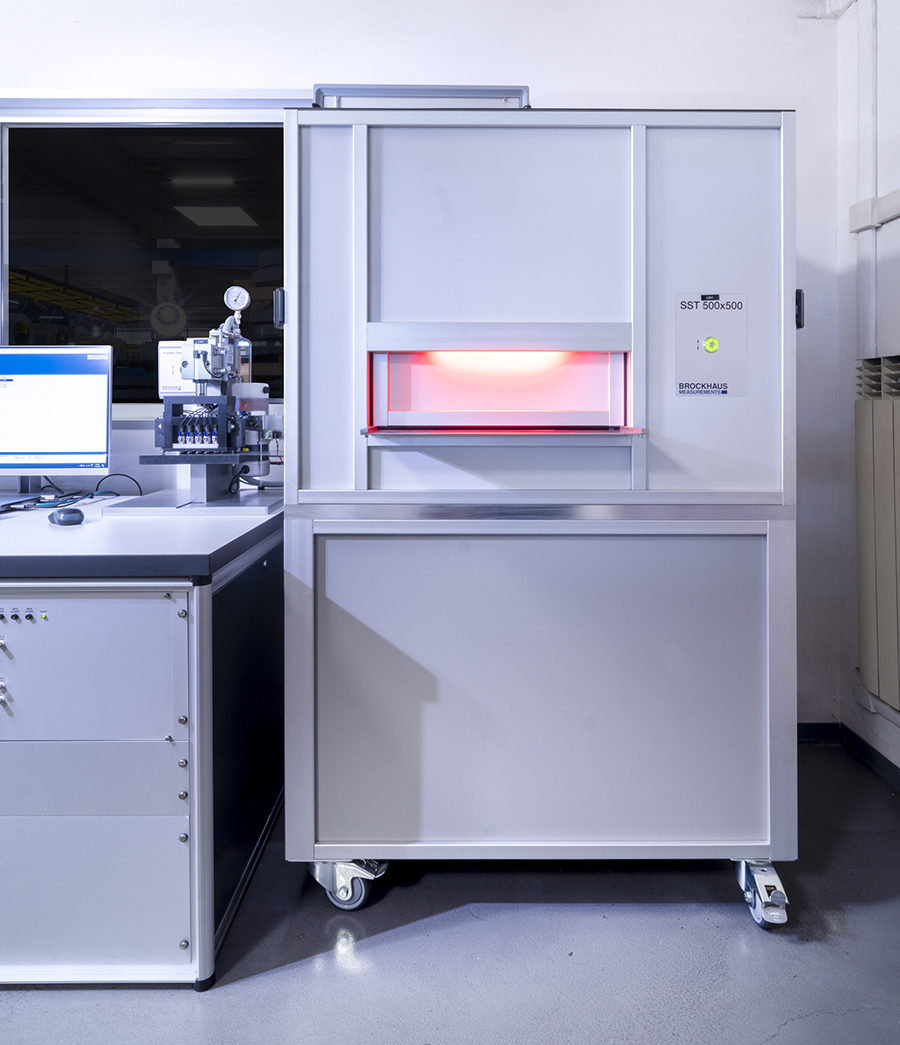

Single Sheet Tester ( SST ) - IEC 60404-3

For the quality control of single sheet electrical steel in 500 x 500mm format.

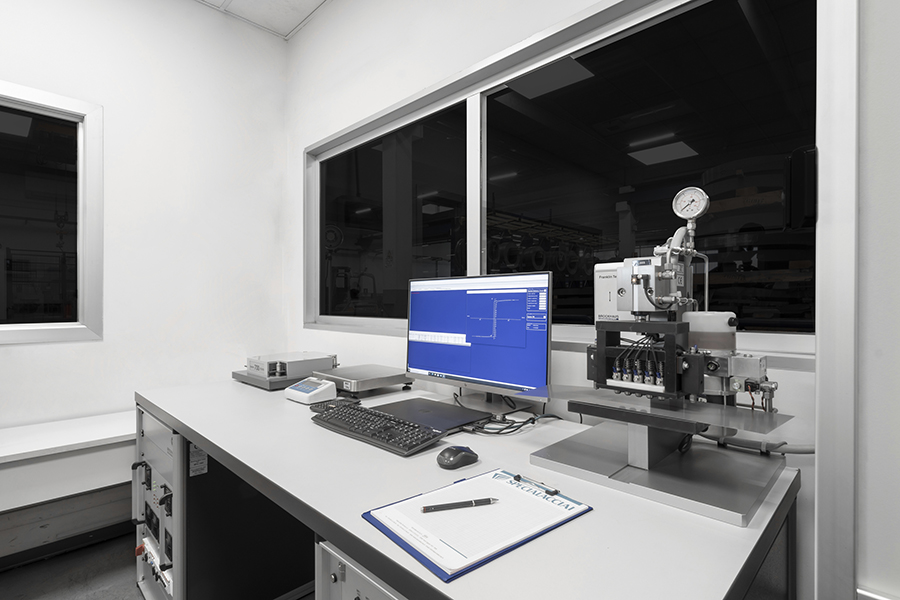

Franklin Tester - IEC 60404-11

Determination of surface resistance of individual samples of electrical and quality control of insulation coating.

Core loss testing – IEC 60076-1

A quick and efficient method to determine and guarantee the losses found in the magnetic core. Core loss testing is made according to the design and electrical values given by our customers.

Noise Test – IEC 60076-10

On request a noise test can be carried out in our anechoic chamber. 10 microphones are placed around the core to guarantee sound pressure at a distance of one meter as indicated by the customer.

Quality of the product

Specialacciai guarantees the quality of its products by selecting high-end electrical steel, using cutting edge technology and specialized personnel with many years of experience in the production of magnetic cores.

Quality Control

The entire production process, from the cutting of the Coil, to the Final Testing and Shipping, is constantly monitored and assessed to meet the necessary criteria in order to ensure the final product and meet the customer requirements.

Cutting precision

Over the last 5 years Specialacciai has completely renewed its cutting lines with the finest machinery and the latest innovation and technology available on the market.

Packaging and shipment care is our utmost concern.

Attention to packaging is a key factor in our process; we have an internal procedure that custom packs our goods based on their final destination.This may include the following steps:

- The VCI paper is placed around the core yoke.

- The silica gel is used inside the core packing to absorb the air humidity.

- The VCI paper is folded and fixed with adhesive tape so the core yoke is completely covered by VCI paper.

- The core is manually stretched with several layers of stretch film, so the core yoke is fully covered.

- Temporary feet and support for the limbs are used to avoid problems during the transportation.

- The core is fixed to the truck with the belts according to our procedure.

ISO 9001:2015