Innovation & Technology

- Home

- Specialacciai

- Innovation & Technology

Empowering core's transformation

Specialacciai is Continuously investing in innovation and technology in order to expand its presence and technological capability and to build a highly efficient organisational structure which maximizes efficiency and increases its competitiveness.

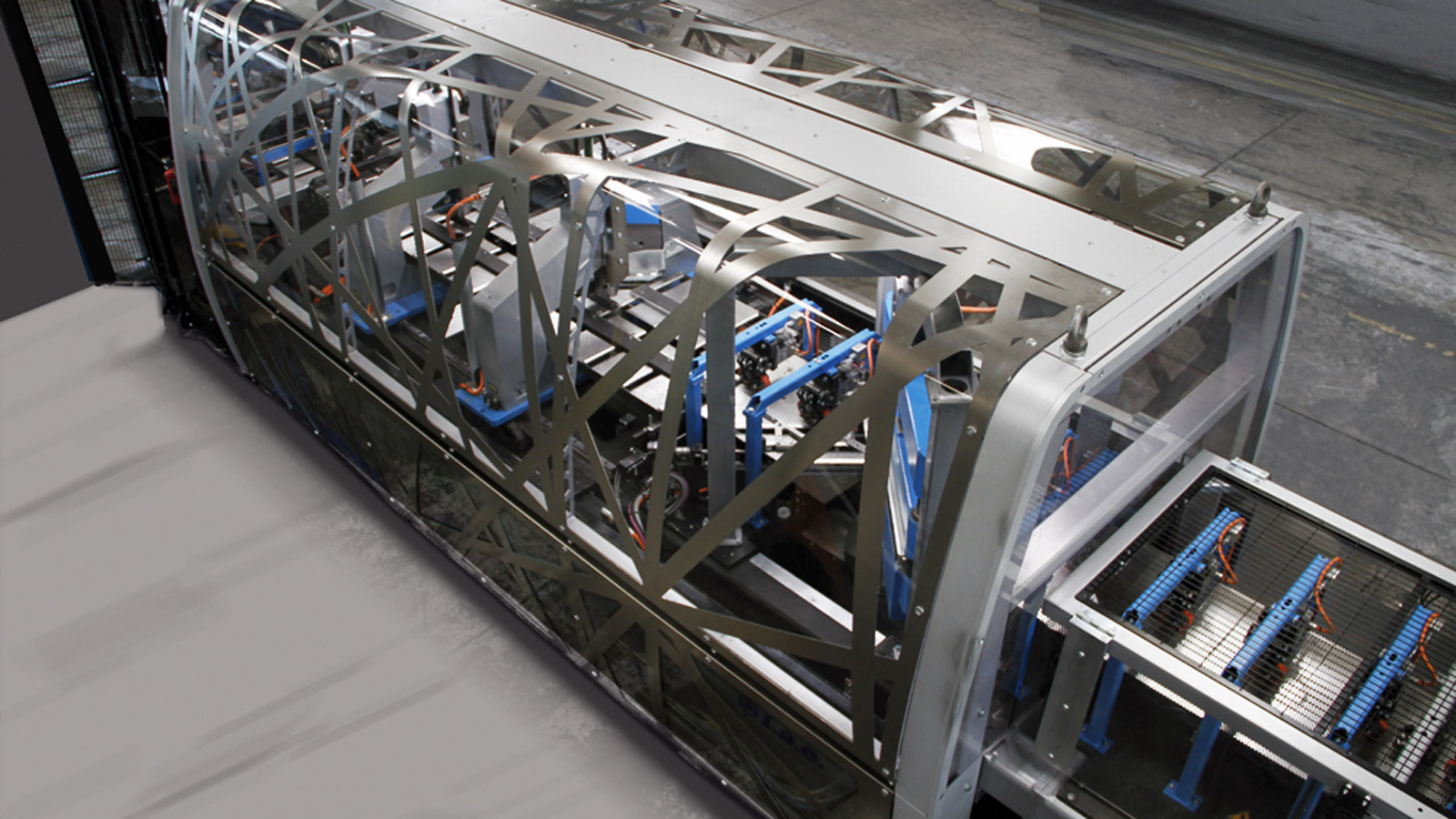

In the recent years all our cutting lines have been replaced with the latest high-tech machinery in order to improve our performance and guarantee the increasing market demands.

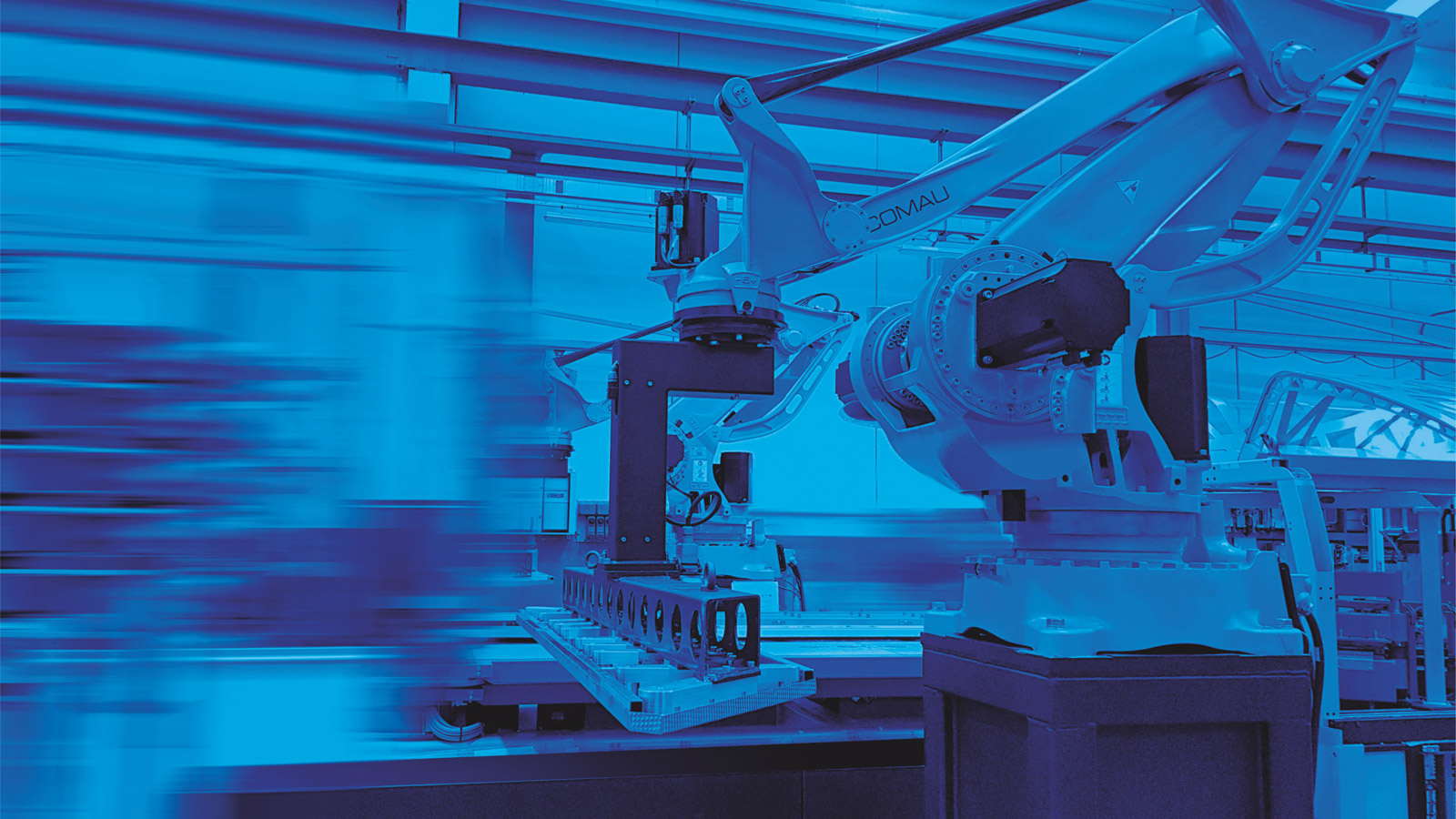

Investing in automation and incorporating automatic system has enabled Specialacciai to increase it’s efficiency and reduce lead time and cost of production.

Today Specialacciai has automatic lines for cutting and assembling 4 cores simultaneously as well as other technologically advanced tools for the control and processing of electrical steel. Specialacciai is investing not only in the renewal of machinery and in the automation of cutting and assembly lines, but also in the acquisition of cutting edge information technology for the digitization of all company activities, from technical office to the finance and production departments.

The administration of MES (Manufacturing Execution System) in Specialacciai is part of an investment project into vast information technologies that embraces a new ERP management system. The MES is connected to the ERP and communicates with the production lines, acquiring all the information necessary for the correct management and traceability of each individual order.

Specialacciai has always believed in the importance of investing in innovation, technology and the quality of the finished product and to direct production towards customization and constant attention to every single detail.